Employee Spotlight: Eric Savage

We had so much fun bragging about one of our amazing employees in our last post that we couldn’t wait to do it again. Quincy Recycle has always put a great deal of focus on safety. Without it, we can’t operate at the high levels needed to provide industry-leading customer service to our partners. So, today we are going to spend some time getting to know an employee who puts safety first. Meet Eric Savage!

Eric works in our New Haven, IN facility, and has been with Quincy Recycle for 6 years. He currently serves as the Operations Manager and is always looking for new and innovative ways to help his team stay safe at work.

Quincy Recycle’s Core Values

If you’ve read our blog in the past, then you may have heard us talk about our core values. Our core values are at the heart of what we do each and every day. The entire team at Quincy Recycle is extremely committed to our core values and Eric is certainly no exception.

Focused on Safety

Eric is extremely dedicated to maintaining a safe working environment for his team, which aligns well with our first core value, Alive and Well. Safety in the workplace is ever-changing, especially in recent months and Eric’s tireless commitment to this core value is why we are excited to feature him today.

“Eric’s number one priority is making sure his teammates make it home to their partners every day. He is always innovating production plans focused around the foundation of safety and our number one core value, Alive and Well.” — Michael Malloy (General Manager, Quincy Recycle)

Let’s learn more about Eric!

1. What does a typical day at work look like for you?

My typical day consists of checking in on all my employees seeing how their day is going and if there is anything I can do to help. I also spend a lot of my time tracking production, managing inventory, and resolving any issues that come up throughout the course of the day.

2. How would you describe the culture at Quincy Recycle?

Supportive. We are only as strong as our weakest link. At Quincy Recycle, we want everyone to be successful and enjoy coming to work each day.

3. Are there any big projects you are currently working on?

My maintenance team and I have been working on developing new and updating existing training procedures and preventive maintenance forms for all of our stationary and mobile equipment. The new and updated forms will help with training our staff on how to safely operate and maintain their equipment, reducing the risk of injury as well as potential downtime and repair costs should the equipment become damaged.

4. What’s one thing you’d like prospective employees to know about the company?

Your career is what you make it and opportunities at Quincy Recycle are endless. Quincy Recycle does a great job identifying strengths of employees and putting them in positions where they can utilize those strengths.

5. When you’re not at work, how would we find you spending your free time?

I spend my free time with my wife and kids. We enjoy being outside hiking and camping. My wife and I are very competitive and play in various sporting leagues such as Softball, Volleyball, Golf, and Bowling.

Alive and Well

We are all proud of Eric and grateful to have him as part of our team. His commitment to our first core value, Alive and Well helps make us a better company. We’re in the recycling business, but without our people, we wouldn’t be able to do what we do.

Our culture and core values define who we are at Quincy Recycle. Recently, we put together a video showcasing the Alive and Well core value and what it means to the team. Check it out!

Are you interested in learning more about Quincy Recycle?

Check out our About Us page for company background and our Careers page for information on how to join our team.

Quincy Recycle is in the business of solving waste stream problems for manufacturers. With in-house logistics, equipment distribution, and food waste processing, we are a one-stop-shop in helping our partners maximize their financial and sustainability goals from coast-to-coast.

Don’t forget to subscribe to our blog for the latest in industry news, recycling trends, and more!

Employee Spotlight: Kelsey Hayes

Kelsey Hayes truly owns her role as our Financial Controller and the respective scope of responsibilities she and her team share in ensuring the accuracy of our financial data and the integrity of our processes and transactions. She has a thirst for knowledge and understanding in all aspects of our business, and she is committed to learning and continuous improvement. In the 18 plus months that she has been our Financial Controller, Kelsey has built a strong, balanced, and dynamic team where voices are heard, strengths are leveraged, and internal controls are protected. Phil Hildebrand said of her, “Kelsey’s determination, sense of urgency, and high orientation for detail give me confidence that our team is on top of the day-to-day activities with a focus on making it easy for our vendors and our customers to do business with us.”

When did you start with Quincy Recycle?

July 2017

What was your job title when you started?

Financial Accountant

What is your current title?

Financial Controller

If you had to pick one, which Core Value is your favorite and why?

Alive & Well. Safety is the top priority at Quincy Recycle but this core value also represents work-life balance. I am happy to work for a company that values me as a person and wants to see me succeed in all facets of life.

What was the most challenging thing to learn in your roles?

Learning a new accounting system and the recycling industry in general was challenging during my first few years at Quincy Recycle. As my role has changed over the last 6 years, I have been continually challenged in new ways and never know when a new learning moment will arise.

What was the most surprising or fun thing to learn?

I am constantly amazed by the amount of companies Quincy Recycle works with. I think it is fascinating to walk into a store and recognize companies/brands of products on the shelves that I have worked with in my role at QRP.

What’s your favorite part about working at Quincy Recycle?

The people and the ability for unlimited growth.

What would you like prospective employees to know about Quincy Recycle?

Hard work does not go unnoticed at Quincy Recycle. If you put in the time, effort, and energy, you will realize great things at this company.

What are some of your hobbies outside of work?

Spoiling my 8 nieces & nephews, playing volleyball year-round, and traveling! My husband and I are going on an Alaskan cruise this Summer!

What’s the best piece of advice you’ve ever read or received?

Keep the mentality “If it is to be, it is up to me”. If you want something in life, you are the only one that can make it happen!

If you had to pick a song to portray the culture of Quincy Recycle, what would it be and why?

“We Are Family” by Sister Sledge

How Quincy Recycle Fits Into Your Circular Economy Plan

In recent years, the circular economy concept has gained significant traction.

But what exactly does it mean? At its core, a circular economy seeks to shift from the traditional linear “take-make-dispose” approach to a more sustainable model based on recycling, reusing, and reducing waste. A circular shift requires businesses to rethink their current practices and look for ways to improve sustainability goals.

In this blog, we’ll shed light on how Quincy Recycle can be your trusted partner in achieving your circular economy plan.

Waste Reduction Through Material Recovery

Millions of tons of reusable materials end up in landfills every year. Quincy Recycle is dedicated to sourcing and collecting these materials before they go to waste.

Through advanced material recovery techniques, we help identify recyclable materials within your waste stream and recover them. Our team works with customers to collect various types of plastic, metal, paper, cardboard, and other materials for repurposing or reuse. We work with national partners in a circular approach to ensure that valuable resources are extracted and reintegrated into the supply chain.

Overall, material recovery helps businesses reduce their waste output, save on landfill fees, and optimize the use of resources.

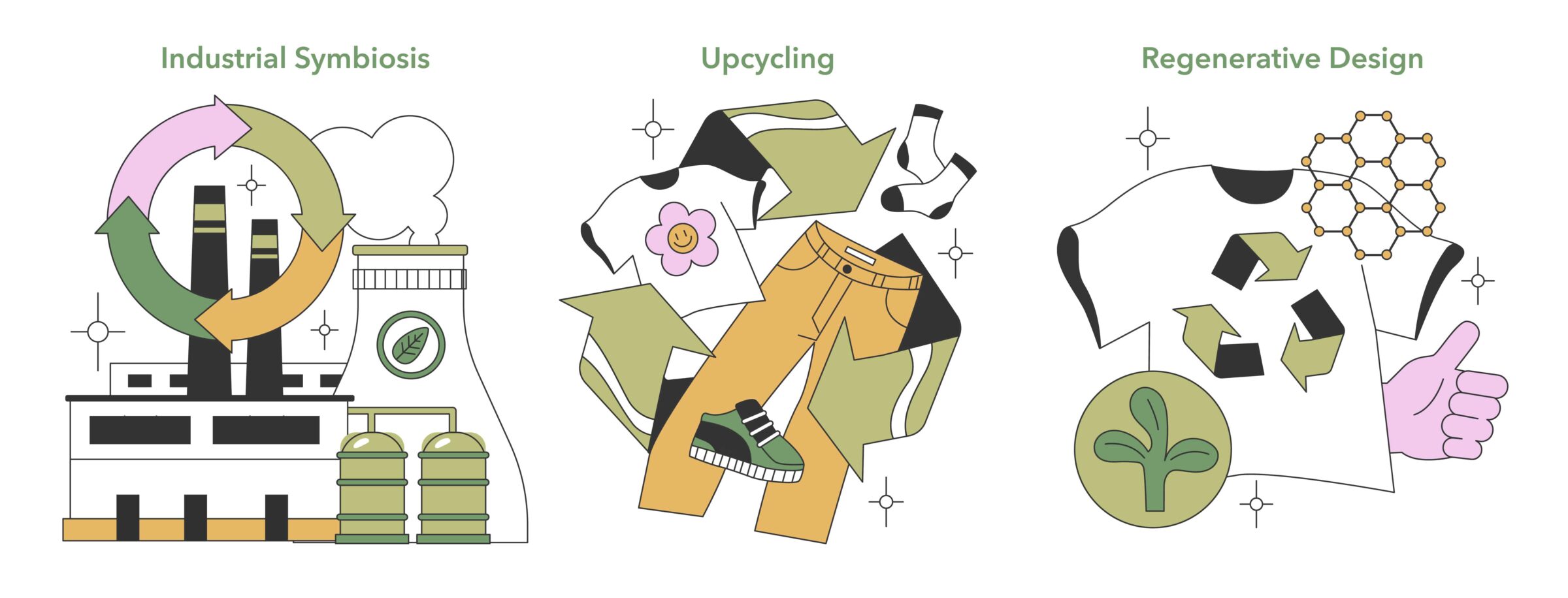

Sustainable Resource Management with Industrial Symbiosis

Industrial symbiosis offers a unique opportunity for businesses to exchange and utilize each other’s waste as valuable resources. Quincy Recycle contributes to industrial symbiosis in a circular economy by connecting and collaborating with different industries.

For example, imagine a plastic manufacturing company generating a significant amount of waste in their process. Instead of disposing of the waste, Quincy Recycle identifies a symbiotic opportunity by connecting the plastic manufacturer with another company needing plastic raw materials, such as a packaging company.

We then facilitate the transfer of plastic waste to the packaging company, which uses it as a valuable resource to produce new packaging materials. Multi-company collaboration allows the plastic manufacturer to reduce waste and disposal costs and enables the packaging company to obtain cost-effective raw materials.

Our industrial symbiotic relationships help businesses close the loop in their production cycles. Waste from one industry becomes a valuable resource for another, and everyone involved becomes part of a more sustainable circular economy.

Protecting Your Image and the Bottom Line

Circular economy plans can promote a business’s reputation and brand image as an environmentally responsible entity. In an increasingly conscious marketplace, consumers and stakeholders demand sustainable practices and are more likely to support businesses prioritizing environmental stewardship. Working with a reputable recycling partner like Quincy Recycle allows businesses to strengthen their brand value and differentiate themselves from competitors.

Implementing a circular economy plan with Quincy Recycle can also bring economic benefits. Businesses can efficiently manage their waste streams, minimize disposal and hauling costs, and potentially generate additional revenue by selling recycled materials or by-products.

Why Work with Quincy Recycle on a Circular Economy Plan?

We offer customized solutions and recycling expertise to meet your needs, such as:

1. Material Evaluation

Quincy Recycle has a team of recycling experts who can evaluate your waste streams and design tailored recycling solutions for your organization. We understand the unique challenges different industries face and can guide you in optimizing your recycling processes.

2. Comprehensive Recycling Services

Whether you need assistance with single-stream recycling, document destruction, or specialized recycling of specific industrial materials, Quincy Recycle has you covered. We offer a wide range of recycling services to meet your needs and help you focus on your core business operations.

3. Transparent Reporting

We believe in transparency. You will receive detailed reporting on the volumes and types of materials collected, suggestions on waste stream management, and updates on how to continue achieving your circular economy goals.

4. Long-Term Collaboration

Lasting relationships with our partners are a driving force behind what we do. We are committed to continuously improving our recycling services and working closely with you to meet your circular economy goals. Our dedicated team of recycling experts will be with you every step of the way.

Are you interested in creating a Sustainability Plan? We can help.

We have helped industrial and manufacturing companies make a positive impact on the future of our planet. From waste reduction and cost savings to promoting sustainable supply chains and environmental stewardship, we have the expertise and resources to help you achieve your circular economy goals.

Contact Quincy Recycle today at 800.311.6097 and let us be your trusted partner in industrial recycling. Together, we can create a more sustainable future for generations to come.

Employee Spotlight: Kyle Howell

When our leaders embody our Core Values, they help lift up everyone around them. That is certainly the case with Kyle Howell. He is a shining example of putting the values front and center. General Manager Michael Malloy says of Kyle, “He has grown with Quincy Recycle from a shift supervisor to Operations manager because of his hard work, determination to win and his continuous dedication to learning. He has built a great team around him and is always focused on our core values. ” Thank you for continuing to be a great example, Kyle!

When did you start with Quincy Recycle?

May 2021

What was your job title when you started?

Plant Supervisor

What is your current title?

Operations Manager

If you had to pick one, which Core Value is your favorite and why?

Alive & Well Being in operations the biggest win I can have every day is getting my team home safe to their families. I can’t just talk safety; I need to live it through my actions.

What was the most challenging thing to learn in your roles?

Managing the person and not the job. Every person needs managed in the way that will help them succeed.

What was the most surprising or fun thing to learn?

Marketing material has been a challenging but fun thing to learn. Connecting with other people that want to provide sustainability has helped my team provide the best waste management solutions to our vendors.

What’s your favorite part about working at Quincy Recycle?

Being able to teach people about the benefits of recycling and coaching them on the best ways to provide sustainability to their business.

What would you like prospective employees to know about Quincy Recycle?

We treat our team members like people, not numbers. We genuinely want people to succeed and work diligently to help them to achieve their goals.

What are some of your hobbies outside of work?

I enjoy being outdoors and spending time with my friends and family. I’ve picked up golfing the last few years and enjoy the challenges that come with it. I will occasionally play recreational baseball and ice hockey when available.

What’s the best piece of advice you’ve ever read or received?

Stop saying you don’t have time and start saying it’s not a priority. You will make time for things that are a priority. If someone says they don’t have time what I hear is it’s not a big enough priority yet.

If you had to pick a song to portray the culture of Quincy Recycle, what would it be and why?

Avicii- The Nights. Make a positive impact everywhere you go. Live life to the fullest and live a life people will remember!!