The Importance Of Safety In The Recycling Industry

At Quincy Recycle, safety is one of our top priorities. Recycling may not be one of the first industries that come to mind when you think about jobs with a high risk to health and safety. But, did you ever stop and think about the types of materials collected and sorted?

In their most recent report published in December 2019, the Bureau of Labor Statistics rated the recycling industry as the 5th most dangerous in America. Today we will talk about why safety is so important to us by highlighting some of the common health and safety risks associated with the recycling industry and how we address them in our facilities.

5 Common Health and Safety Risks in Recycling

1. Large and Moving Machinery

Processing large quantities of plastic, metal, and other recyclable materials requires big machinery. Compactors, balers, conveyor belts, and sorting machines are regular fixtures in recycling plants. All of these can cause injury if adequate operating and maintenance procedures are not put in place.

Robust safety protocols and checklists are in place across all Quincy Recycle locations. Equipment is inspected regularly and when maintenance or repair is required, a “lock-out and tag-out” protocol is strictly enforced to ensure the machinery is in proper working order before being put back into service. From their first day of employment, each member of our team goes through extensive safety and operator training. Training is ongoing and takes place on a regular and frequent basis at each of our facilities.

2. Trucks and Other Big Vehicles

In order to haul and move large loads of material, you need trucks, forklifts and other big vehicles. Any time you have large vehicles in the same place as pedestrians you have a safety risk.

Operator awareness is a top priority at Quincy Recycle. From training to operator certifications, we make sure anyone operating a large vehicle at our facility is qualified and adhering to necessary safety protocols. We also utilize tools like glad hand locks. Trailers come and go from our facilities all the time and a glad hand lock prevents a truck from hooking up to the trailer while someone is inside working.

3. Repetitive Motion

Recycling workers move a lot. They reach, twist, jump, and bend to sort and process items daily. The absence of a well-organized and ergonomic workspace can lead to injury over time.

We spend a lot of time training and promoting best safety practices at Quincy Recycle, and that includes steps to prevent injury due to repetitive motion. Our plants are designed with a layout to help our team members be as efficient as possible, which goes a long way in helping keep them safe and injury-free.

4. Respiratory Hazards

Recyclable materials produce a lot of dust. Without proper safety equipment and ventilation, small particles from materials we process such as paper, plastic, cardboard, and other contaminants can pose harm to workers.

Quincy Recycle provides all employees with dust masks and safety glasses to protect against airborne contaminants. In addition, our facilities are outfitted with air ventilation systems to help remove dust from the air key locations throughout the plant.

5. Biohazards

Sorting through mixed-commodity loads presents some risks. Sharp objects, industrial chemicals, and other biohazards can be present and must be handled carefully to avoid injury.

We take a proactive approach to make sure we know exactly what is coming into our facilities. Utilizing safety data sheets, our team can confirm the former contents of products such as fiber or plastic drums to ensure nothing comes into the plant that shouldn’t. We also provide our team with Personal Protective Equipment (PPE) to help keep them safe when handling the wide variety of material that comes through our plants each day. Along with PPE, you’ll also find first-aid and bloodborne pathogen kits in each of our facilities.

Quincy Recycle Promotes A Safety-Focused Culture

Safety is part of our culture at Quincy Recycle. In fact, it is one of our core values. We don’t take the risks associated with our industry lightly and have put a lot of time and energy into making sure our facilities are safe.

“It starts at the top. Everyone across our organization is fully committed to running a safe operation. Our first core value is “Alive and Well” because safety is part of everything we do at Quincy Recycle. Many of our facilities boast lengthy safety records which is a real testament to the buy-in and dedication from everyone on the team.” – Philip J. Hildebrand, Jr., Quincy Recycle

Why is this so important?

To us, it’s simple – our team is our family. Keeping them safe is our first priority. And, in turn, our commitment to health and safety allows us to provide consistent service our partners can depend on whenever they need us.

Are you ready to take the first step toward achieving your sustainability goals?

Contact us today and together we can make an impact. We offer a wide variety of services designed to meet your specific needs.

Don’t forget to subscribe to our blog for the latest in industry news, recycling trends, and more!

Employee Spotlight: Dan Parker

Dan Parker serves as an ALC (Account Logistics Coordinator) in our West Bend location. When asked about Dan, General Manager Marshall Harting said, “Dan has been a lifelong friend and someone I have always been able to count on to help with any task. Five years ago he joined my team in West Bend and has brought that same mentality from day one. He is always willing to go above and beyond his specific job duties and takes great pride in helping fellow team members be successful. Dan is the embodiment of what it means to be a great teammate; all you have to do is ask any one on our team!” It’s easy to see that Dan embodies our Core Values and is a tremendous asset to the team!

When did you start with Quincy Recycle?

March 2019

What was your job title when you started?

Account logistics coordinator

What is your current title?

Account logistics coordinator

If you had to pick one, which Core Value is your favorite and why?

One Team One Dream One Family– This is my favorite core value because of the way I came into Quincy West Bend. We were a whole new team and learning together. We had a leader that made us a family.

What was the most challenging thing to learn in your roles?

Think the most challenging thing of learning the roll was to handle the day with all the ups and downs and still make sure all the I’s were dotted and T’s were crossed in Rimas.

What was the most surprising or fun thing to learn?

When I started i knew as much about recycling as any home owner with a recycling bin. I loved learning about all the different paper grades and commodities. Had an amazing person sit down with me and take his time explaining everything he could in the two hours we had. Since then I have made sure to go out and see every new item we bring in. It is always changing as the team brings in new accounts.

What’s your favorite part about working at Quincy Recycle?

The team/family I get to work with everyday. Our team in West Bend has such a family feel to it. May not always agree with each other but that leads to some of the best out comes because we work together. And our family has extended to our Wisconsin team. Great group of people just up the road that is always there to help or bounce ideas off. Plus six other teams i can call at anytime.

What would you like prospective employees to know about Quincy Recycle?

That you have a team behind you and a new family. Doesn’t matter what roll you have you matter to the team. I have never felt that so much any where else.

What are some of your hobbies outside of work?

In my free time I love watching my son Weston play sports and practicing with him. Also enjoy hanging out with friends, hiking and being outdoors.

What’s the best piece of advice you’ve ever read or received?

I have two, one that has stuck with me for years and one that I read a few years back. To make a difference in someone’s life, you don’t have to be brilliant, rich, beautiful, or perfect. You have to care. My happiness is my reflection on the suffering during my journey and knowing that I never quit nor was I guided by anybody on this earth.

If you had to pick a song to portray the culture of Quincy Recycle, what would it be and why?

Good Day by Forrest Frank

Employee Spotlight: Kelsey Hayes

Kelsey Hayes truly owns her role as our Financial Controller and the respective scope of responsibilities she and her team share in ensuring the accuracy of our financial data and the integrity of our processes and transactions. She has a thirst for knowledge and understanding in all aspects of our business, and she is committed to learning and continuous improvement. In the 18 plus months that she has been our Financial Controller, Kelsey has built a strong, balanced, and dynamic team where voices are heard, strengths are leveraged, and internal controls are protected. Phil Hildebrand said of her, “Kelsey’s determination, sense of urgency, and high orientation for detail give me confidence that our team is on top of the day-to-day activities with a focus on making it easy for our vendors and our customers to do business with us.”

When did you start with Quincy Recycle?

July 2017

What was your job title when you started?

Financial Accountant

What is your current title?

Financial Controller

If you had to pick one, which Core Value is your favorite and why?

Alive & Well. Safety is the top priority at Quincy Recycle but this core value also represents work-life balance. I am happy to work for a company that values me as a person and wants to see me succeed in all facets of life.

What was the most challenging thing to learn in your roles?

Learning a new accounting system and the recycling industry in general was challenging during my first few years at Quincy Recycle. As my role has changed over the last 6 years, I have been continually challenged in new ways and never know when a new learning moment will arise.

What was the most surprising or fun thing to learn?

I am constantly amazed by the amount of companies Quincy Recycle works with. I think it is fascinating to walk into a store and recognize companies/brands of products on the shelves that I have worked with in my role at QRP.

What’s your favorite part about working at Quincy Recycle?

The people and the ability for unlimited growth.

What would you like prospective employees to know about Quincy Recycle?

Hard work does not go unnoticed at Quincy Recycle. If you put in the time, effort, and energy, you will realize great things at this company.

What are some of your hobbies outside of work?

Spoiling my 8 nieces & nephews, playing volleyball year-round, and traveling! My husband and I are going on an Alaskan cruise this Summer!

What’s the best piece of advice you’ve ever read or received?

Keep the mentality “If it is to be, it is up to me”. If you want something in life, you are the only one that can make it happen!

If you had to pick a song to portray the culture of Quincy Recycle, what would it be and why?

“We Are Family” by Sister Sledge

How Quincy Recycle Fits Into Your Circular Economy Plan

In recent years, the circular economy concept has gained significant traction.

But what exactly does it mean? At its core, a circular economy seeks to shift from the traditional linear “take-make-dispose” approach to a more sustainable model based on recycling, reusing, and reducing waste. A circular shift requires businesses to rethink their current practices and look for ways to improve sustainability goals.

In this blog, we’ll shed light on how Quincy Recycle can be your trusted partner in achieving your circular economy plan.

Waste Reduction Through Material Recovery

Millions of tons of reusable materials end up in landfills every year. Quincy Recycle is dedicated to sourcing and collecting these materials before they go to waste.

Through advanced material recovery techniques, we help identify recyclable materials within your waste stream and recover them. Our team works with customers to collect various types of plastic, metal, paper, cardboard, and other materials for repurposing or reuse. We work with national partners in a circular approach to ensure that valuable resources are extracted and reintegrated into the supply chain.

Overall, material recovery helps businesses reduce their waste output, save on landfill fees, and optimize the use of resources.

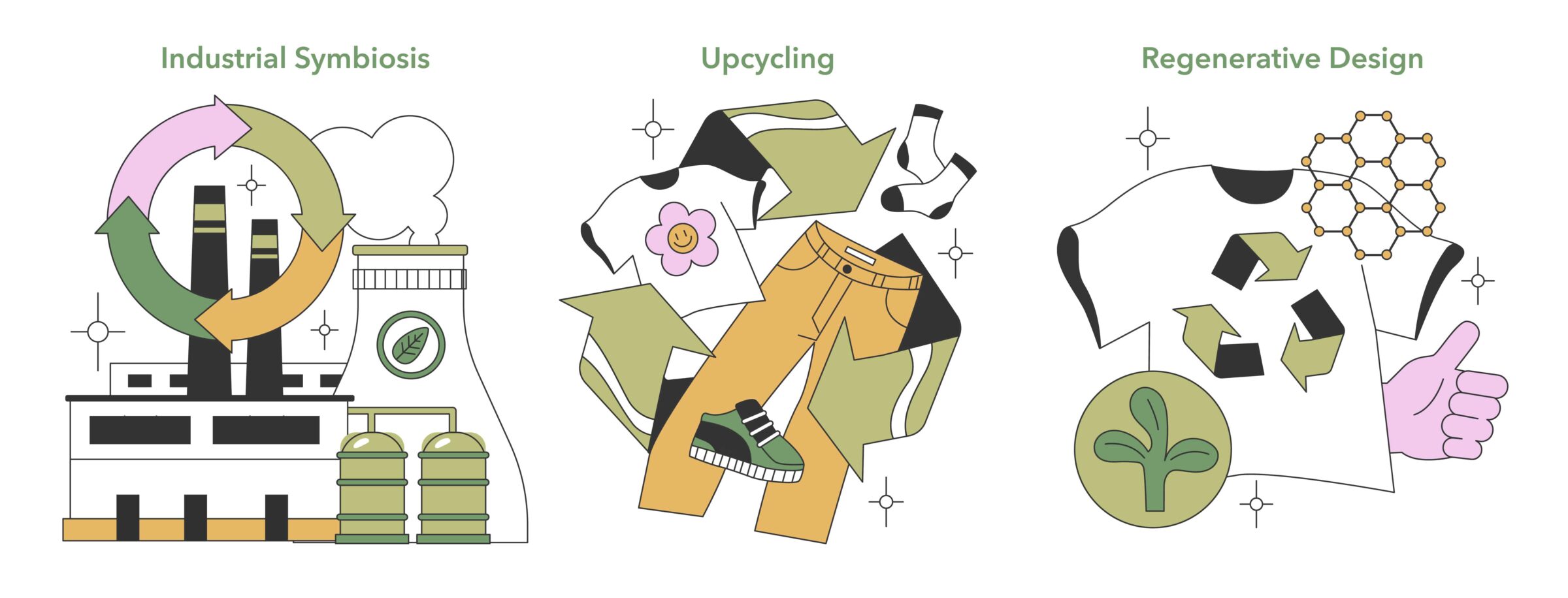

Sustainable Resource Management with Industrial Symbiosis

Industrial symbiosis offers a unique opportunity for businesses to exchange and utilize each other’s waste as valuable resources. Quincy Recycle contributes to industrial symbiosis in a circular economy by connecting and collaborating with different industries.

For example, imagine a plastic manufacturing company generating a significant amount of waste in their process. Instead of disposing of the waste, Quincy Recycle identifies a symbiotic opportunity by connecting the plastic manufacturer with another company needing plastic raw materials, such as a packaging company.

We then facilitate the transfer of plastic waste to the packaging company, which uses it as a valuable resource to produce new packaging materials. Multi-company collaboration allows the plastic manufacturer to reduce waste and disposal costs and enables the packaging company to obtain cost-effective raw materials.

Our industrial symbiotic relationships help businesses close the loop in their production cycles. Waste from one industry becomes a valuable resource for another, and everyone involved becomes part of a more sustainable circular economy.

Protecting Your Image and the Bottom Line

Circular economy plans can promote a business’s reputation and brand image as an environmentally responsible entity. In an increasingly conscious marketplace, consumers and stakeholders demand sustainable practices and are more likely to support businesses prioritizing environmental stewardship. Working with a reputable recycling partner like Quincy Recycle allows businesses to strengthen their brand value and differentiate themselves from competitors.

Implementing a circular economy plan with Quincy Recycle can also bring economic benefits. Businesses can efficiently manage their waste streams, minimize disposal and hauling costs, and potentially generate additional revenue by selling recycled materials or by-products.

Why Work with Quincy Recycle on a Circular Economy Plan?

We offer customized solutions and recycling expertise to meet your needs, such as:

1. Material Evaluation

Quincy Recycle has a team of recycling experts who can evaluate your waste streams and design tailored recycling solutions for your organization. We understand the unique challenges different industries face and can guide you in optimizing your recycling processes.

2. Comprehensive Recycling Services

Whether you need assistance with single-stream recycling, document destruction, or specialized recycling of specific industrial materials, Quincy Recycle has you covered. We offer a wide range of recycling services to meet your needs and help you focus on your core business operations.

3. Transparent Reporting

We believe in transparency. You will receive detailed reporting on the volumes and types of materials collected, suggestions on waste stream management, and updates on how to continue achieving your circular economy goals.

4. Long-Term Collaboration

Lasting relationships with our partners are a driving force behind what we do. We are committed to continuously improving our recycling services and working closely with you to meet your circular economy goals. Our dedicated team of recycling experts will be with you every step of the way.

Are you interested in creating a Sustainability Plan? We can help.

We have helped industrial and manufacturing companies make a positive impact on the future of our planet. From waste reduction and cost savings to promoting sustainable supply chains and environmental stewardship, we have the expertise and resources to help you achieve your circular economy goals.

Contact Quincy Recycle today at 800.311.6097 and let us be your trusted partner in industrial recycling. Together, we can create a more sustainable future for generations to come.